Here are the optimal designs for each size pumping station. Speed - Pumps needed - Distance between pumping stations

Just remember to put a pumping station before your flow rate drops too far, because once it drops below the limit it is impossible to speed up again.Įach small pump can only handle 30 fluid/sec, so you need to use them in parallel. Small pumps pressurize a pipe until it is full again, allowing you to stretch pipes as far as you like without losing speed and capacity. But even pipe-to-ground slows down if you stretch it too far. Pipe-to-ground helps, it counts as 1 pipe and can reach 5.5x as far.

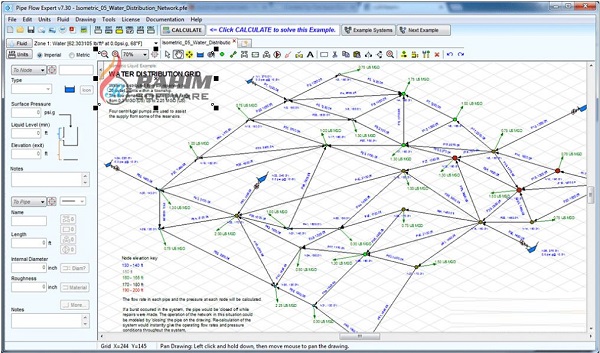

This limit reduces the capacity of long pipes. The exact value depends on the distance between the full pipe (attached to a pump, chemical plant, or merging pipes) and the empty pipe (attached to a chemical plant or steam engine). Pipe Flow Expert is a very powerful design software And analyze networks Pipe Complex where current And Pressure To Solve The system must be balanced.

0 kommentar(er)

0 kommentar(er)